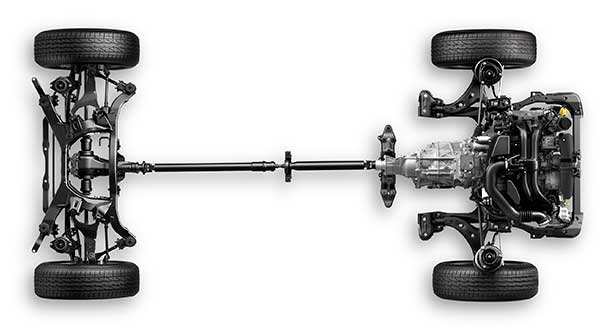

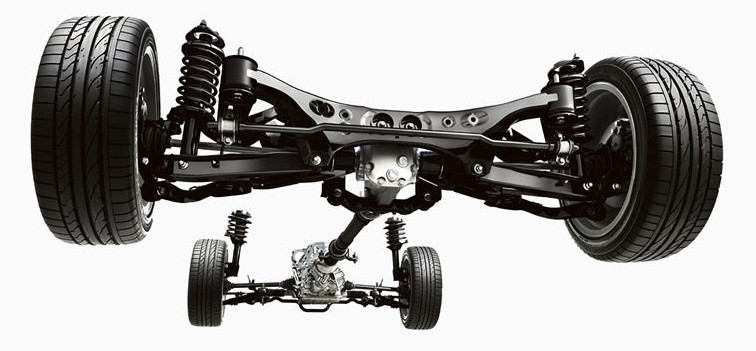

Subaru names it's drivetrain as Symmetrical All-Wheel-Drive. The drive axles are of similar length left-right which allows power distribution to be balanced. This is one of Subaru's best features providing an extra degree of driving agility felt especially through corners.

The Subaru is an All-Wheel-Drive vehicle. It is said that between 17-25% of total power can be lost between the engine - transmission - driveline and wheels, there is additional tax of ~2% for automatic transmissions, like the CVT in this car. For reference FWD and RWD cars have drivetrain losses between 10-15% and 10-18% respectively.

Unlike most tuner cars, the aftermarket engine-power options for the FB20 are limited. With that in mind we, the tuner can turn focus towards improving driveline efficiencies.

There are a number of places where Subaru uses soft bushings to provide a comfortable ride. However by replacing these bushings with harder materials we can improve power transfer, thus reducing AWD drivetrain losses. As with all bushing upgrades, NVH will increase.

Many people tend to replace their pulleys with lightweight versions. The theory behind it, is to reduce the rotating mass allowing for the engine to spin up faster giving more engine response. I like the idea behind replacing all the pulleys with lighter ones, all except the crank pulley.

The OEM crank pulley uses a rubber damper which reduces engine vibration, by removing this dampening, it can cause ill-effects for bearings and valvetrain. The crank pulley instead can be replaced with an aftermarket harmonic dampener. One like Fluidamper or ATI Super damper. The effect would be a wider RPM range of dampening. This, in theory, will provide smoother acceleration, and less vibration allowing for regained power usually lost to destructive vibrations. It has been quoted 1-2% gains with an aftermarket harmonic dampener as well, better engine longevity.

A major place where power delivery can be increased is replacing the OEM rubber engine mounts. These aftermarket parts are usually made from a combination of aluminum and polyurethane bushings, these can significantly reduce engine movement in the engine bay thus giving a increased amount of torque delivered to the rest of the driveline. I myself have not installed these in my car, so I cannot speak to their ease of installation. I am noting them here because of their use in various forms of racing. Noise Vibration and Harshness (NVH) is greatly affected with this option.

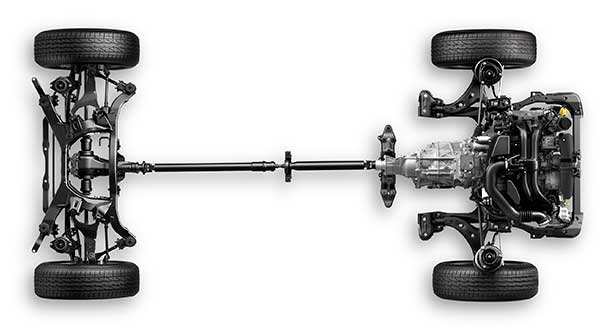

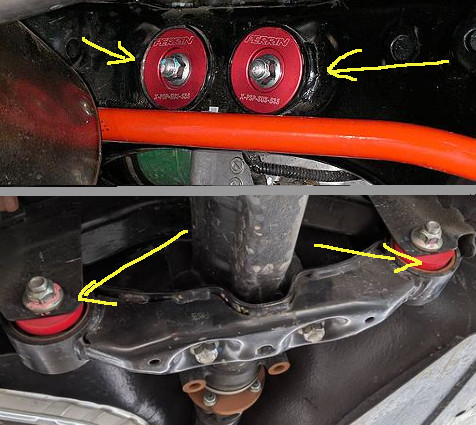

A simple modification is to replace the soft and squishy OEM pitchstop with an aftermarket part. These parts usually come with polyurethane bushings which are stiffer than the OEM rubber. The reduces the amount of engine "bucking" which translates to lost power delivery. There is also the option to use solid aluminum, however this isn't recommended since it will increase NVH significantly through the firewall. Many manufacturers including Subaru (Group N) make these parts, take your pick.

The Subaru transmission mount (CVT or Manual) is a rubber unit which is somewhat hollow. This allows for vibration to be soaked up during normal operation. However like the pitch stop, the OEM transmission mount is soft. It deflects quite significantly under heavy loads causing lost energy transmitted to the rear wheels. You can install a transmission insert, made of polyurethane, or replace the transmission mount with a aftermarket one.

Additionally with the CVT, there is a torque converter in the mix. At certain speeds, at or around 20 mph, some may find a certain wobble feeling happens due to the torque converter not being completely locked up. An aftermarket insert or transmission mount can reduce or remove this wobble/jarring feeling caused by the torque converter and mushy OEM transmission mount. In either case, power delivery will be much better.

Moving further back in the driveline, another place where rubber is used is the driveshaft carrier bushing. Though this isn't completely necessary, it is worth noting that some driveshaft play can be reduced by replacing the OEM bushings with solid aluminum pieces. It has been mentioned that the OEM bushings are very difficult to remove unless they are completely worn. Also the bracket that supports the driveshaft also has a very flexible bushing/bearing to reduce driveshaft vibrations. This bushing replacement should be low on the list of upgrades.

The driveshaft floats on a rubber bushing. This bushing is typically very squishy and deflects under heavy loads. Perrin offers a driveshaft lockdown kit which greaty reduces the driveshaft bushing slop. This simple yet effect bolt-on can help regain some drivetrain efficiency. This modification is Effective when used in combination with other drivetrain bushing upgrades. It is an easy install, a well machined part, and can be easily unbolted.

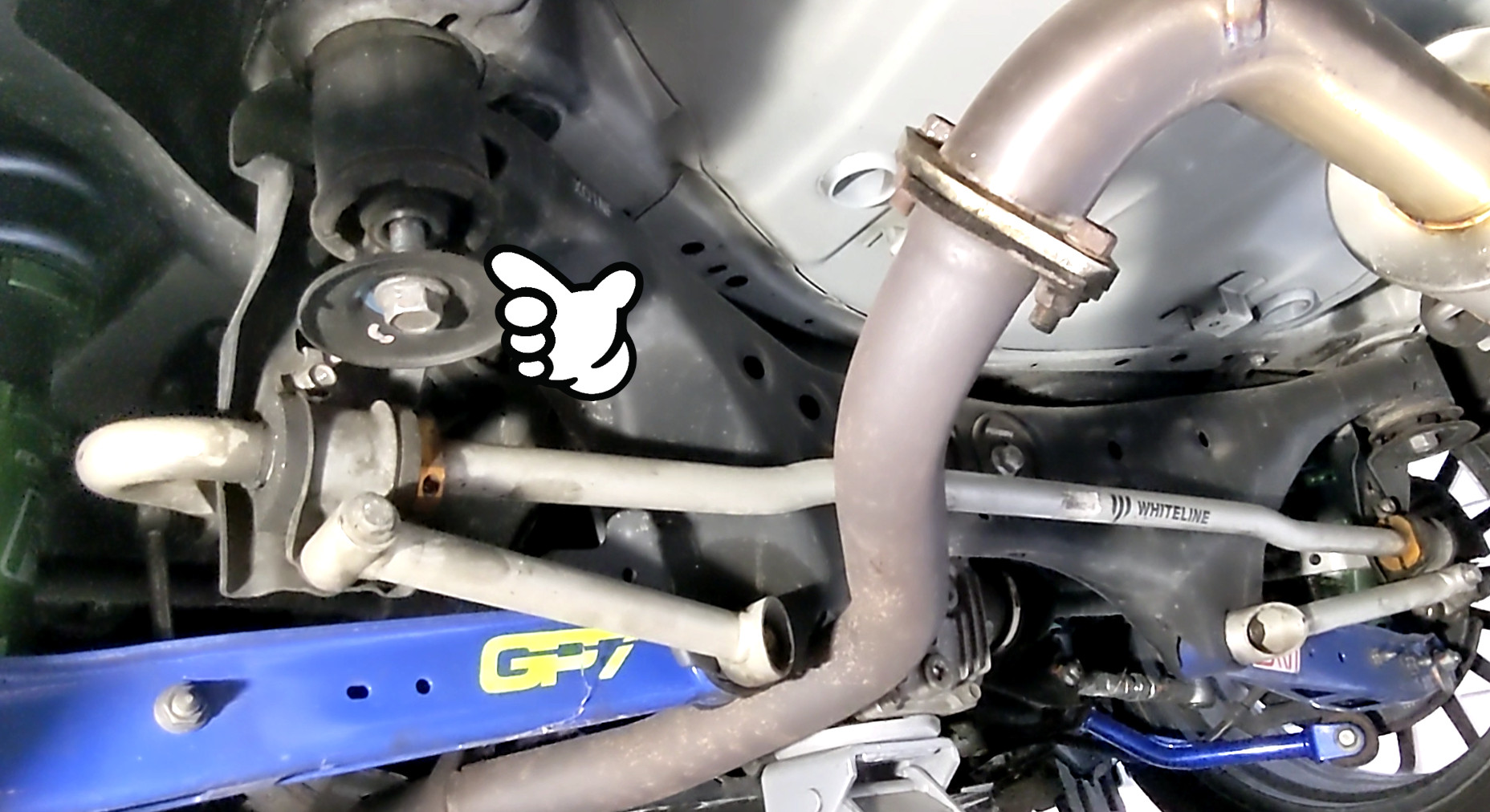

At the very end of the driveline, are the differential brace and bushings. The OEM bushes are made of rubber and have significant flex under load. Here is a place where the tuner can regain a noticeable amount of power. By replacing the rubber bushings in the brace with polyurethane and solid bushings in the mount one can realize a significant amount of torque being delivered to the rear wheels. This is highly recommended, but can be a more involved modification.

BONUS!

While not directly part of the drivetrain, the rear subframe (or crossmemeber) bushings are quite compliant (flexible) and soak up a noticeable amount of torque that the engine produces. By using subframe bushing inserts, or replacing them altogether, the tuner can literally close the gaps of torque loss (due to lost motion.) Upgrading subframe bushings also doubles its effectiveness by tightening up the chassis for handling. Double-Win! 🏆

Not only is the driveline concerned with power delivery to the rear wheels, but also consider these modification to work in conjunction with suspension modifications. All suspension components which are upgraded to use polyurethane or spherical ball joints as bushings will see an additive bump in drivetrain efficiencies, which manifest to the driver as more torque and tigher handling.

Each of these bushings would translate to a 0.5%-2% driveline efficiency. Added together, they definitely increase torque driven to wheels, coupled with suspension modification it is a clear place where the tuner can take advantage and make more power through driveline efficiencies.

Check out this realistic Subaru Impreza AWD Tuning Simulator Back to Subaru Impreza Tuner

Back to Subaru Impreza Tuner